Producers not often get the posh of a clean canvas. Manufacturing traces evolve, tools accumulates, and earlier than lengthy each sq. metre is working time beyond regulation. That’s precisely the place the Compact Palletiser excels. As an alternative of forcing services to reorganise round cumbersome palletising programs, it delivers industrial‑grade efficiency in a fraction of the footprint—with out compromising throughput or flexibility.

Whether or not integrating into an current line or planning a brand new facility, the Compact Palletiser affords a sensible, area‑environment friendly path to automation the place standard programs merely received’t match.

Palletising Designed for Area‑Constrained Amenities

The Compact Palletiser addresses a core manufacturing problem: attaining automated palletising with automated pallet feeding in tight areas. Conventional programs depend on lengthy conveyors and huge buffer zones, limiting structure flexibility. Granta’s answer is intentionally streamlined—combining a low‑profile conveyor association with a excessive‑efficiency robotic arm to create a self‑contained palletising cell that matches the place others can’t.

Its compact footprint makes it best for small or awkward areas. Relying on the configuration, completed pallets may be eliminated manually or by way of low‑profile conveyors, enabling excessive productiveness with out requiring intensive staging areas.

Environment friendly Pallet Elimination for Any Workflow

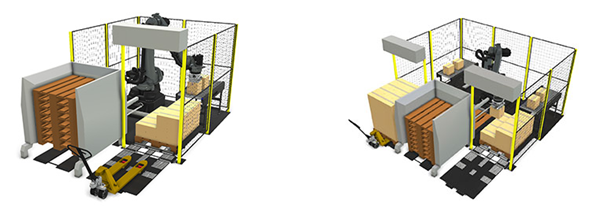

A significant benefit of the Compact Palletiser is its flexibility in how completed pallets are eliminated. Each configuration is designed to work seamlessly with each forklift vans and pallet vans at ground stage. This makes the system uniquely capable of combine into current materials‑dealing with routines the place solely pallet vans or powered pallet vans (PPTs) are secure to make use of. Many manufacturing areas have well being and security necessities that stop using counterbalance forklifts and regular conveyor programs can’t be unloaded with out this or ramps that are each thought to be harmful. Granta Automation has developed this low stage pallet motion system and is the one system on the planet with this low stage automated pallet motion with pallet truck take off for all pallet sorts. Whether or not the power depends on handbook pallet vans, electrical pallet movers, or full forklift operations the compact system covers all necessities.

Modular Configurations Constructed Round Your Manufacturing Wants

The Compact Palletiser is out there in three configurations—every supplied as a single or double lane cell and tailor-made to completely different throughput and automation necessities:

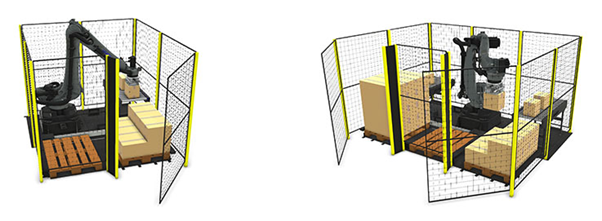

Compact Palletiser Static

The best and most price‑efficient choice. Empty pallets are loaded manually, and full pallets are eliminated by forklift or pallet truck. Preferrred for producers in search of dependable, entry‑stage automation with minimal integration complexity.

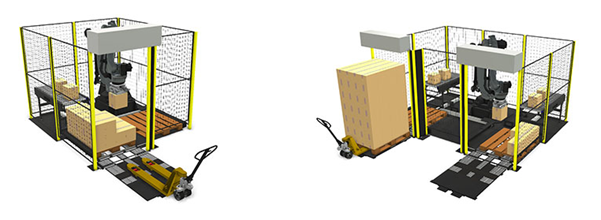

Compact Palletiser Auto

Contains low‑profile conveyors to robotically transport full pallets out of the cell whereas the robotic continues working. Empty pallets may be positioned into the cell manually with out stopping the robotic. This steady‑operation design reduces downtime and boosts throughput—good for quicker‑paced manufacturing environments.

Compact Palletiser Auto with Pallet Feeder

A totally automated answer. With automated pallet feeding and move‑via functionality, the robotic operates uninterrupted, dealing with a number of pallets seamlessly. Designed for top‑velocity, multi‑product traces the place handbook intervention should be saved to a minimal.

Comparability of Compact Palletiser Configurations

| Function | Static | Auto | Auto with Pallet Feeder |

| Footprint | Smallest | Barely bigger; consists of outfeed conveyors | Largest; consists of pallet feeder and outfeed conveyors |

| Automation Stage | Guide pallet loading/elimination | Semi‑automated: pallets fed manually and eliminated robotically | Absolutely automated: pallets fed and eliminated robotically |

| Throughput | Reasonable | Excessive | Very excessive; steady operation |

| Robotic Operation | Stops for pallet modifications | Continues whereas pallets are manually added and eliminated | Uninterrupted operation with automated pallet feed and elimination |

| Product Sorts | Containers, cartons, trays, shrink‑wrapped packs, and many others. | Containers, cartons, trays, shrink‑wrapped packs, and many others. | Containers, cartons, trays, shrink‑wrapped packs, and many others. |

| Preferrred Functions | Entry‑stage automation; restricted manufacturing | Sooner‑paced traces needing steady pallet elimination | Excessive‑velocity, multi‑product traces with minimal handbook intervention |

| Key Advantages | Low price, simple to put in, area‑saving | Lowered downtime, greater throughput, versatile | Most uptime, minimal handbook dealing with, scalable automation |

| Operator Interplay | Guide loading/elimination | Guide loading/elimination | Minimal; largely fingers‑free other than loading stacks of empty pallets and eradicating stacked pallets |

Efficiency and Flexibility With out Compromise

Compact doesn’t imply restricted. The system is engineered for industrial‑power efficiency, dealing with payloads as much as 140 kg. A variety of finish‑of‑arm tooling—vacuum, mechanical, or bespoke—permits it to deal with cartons, trays, shrink‑wrapped packs, and extra.

Superior management software program ensures exact stacking, whereas row‑choose and multi‑choose capabilities speed up cycle instances on demanding traces.

Why the Compact Palletiser Is a Sport‑Changer

In an business the place area, flexibility, and uptime are vital, the Compact Palletiser permits producers to deploy superior excessive velocity palletising in areas beforehand thought-about too small or not secure sufficient. From manually fed static cells to completely automated pallet‑feeding programs, it affords scalable options for each manufacturing stage.

By combining area‑environment friendly engineering with clever management, and low automated pallet shifting via the system Granta Automation’s Compact Palletiser proves that prime‑efficiency automation doesn’t require a big footprint. For area‑restricted services, it’s greater than a palletiser—it’s a strategic enabler of effectivity, security, and operational agility.

In case you’d to debate you automated palletising necessities, be happy to contact us on 01223 499488 or helpline@granta-automation.co.uk and we might be comfortable to assist.