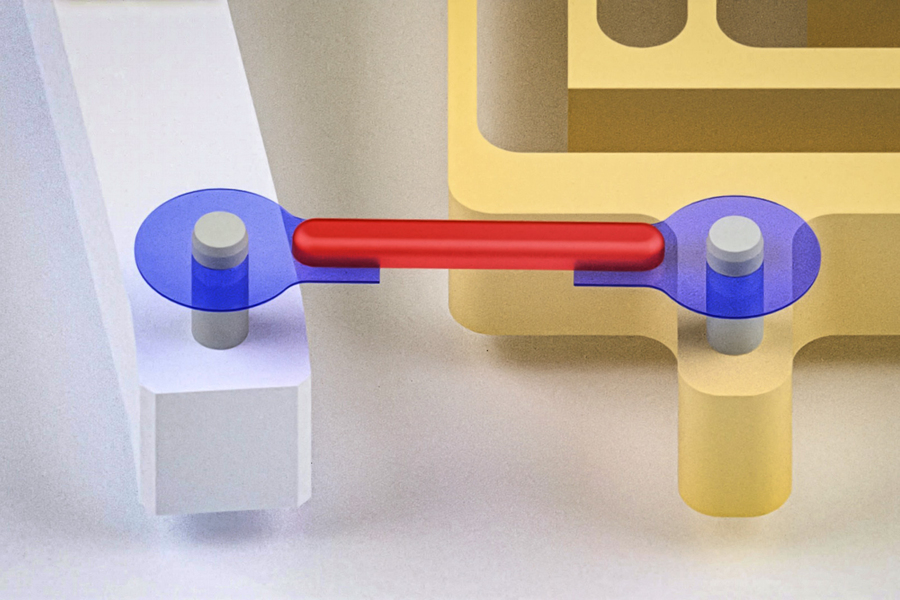

Researchers have developed synthetic tendons for muscle-powered robots. They hooked up the rubber band-like tendons (blue) to both finish of a small piece of lab-grown muscle (purple), forming a “muscle-tendon unit.” Credit score: Courtesy of the researchers; edited by MIT Information.

Our muscle tissue are nature’s actuators. The sinewy tissue is what generates the forces that make our our bodies transfer. Lately, engineers have used actual muscle tissue to actuate “biohybrid robots” constructed from each dwelling tissue and artificial components. By pairing lab-grown muscle tissue with artificial skeletons, researchers are engineering a menagerie of muscle-powered crawlers, walkers, swimmers, and grippers.

However for essentially the most half, these designs are restricted within the quantity of movement and energy they’ll produce. Now, MIT engineers are aiming to offer bio-bots an influence elevate with synthetic tendons.

In a examine which just lately appeared within the journal Superior Science, the researchers developed synthetic tendons constructed from robust and versatile hydrogel. They hooked up the rubber band-like tendons to both finish of a small piece of lab-grown muscle, forming a “muscle-tendon unit.” Then they related the ends of every synthetic tendon to the fingers of a robotic gripper.

Once they stimulated the central muscle to contract, the tendons pulled the gripper’s fingers collectively. The robotic pinched its fingers collectively thrice quicker, and with 30 instances higher pressure, in contrast with the identical design with out the connecting tendons.

The researchers envision the brand new muscle-tendon unit might be match to a variety of biohybrid robotic designs, very similar to a common engineering factor.

“We’re introducing synthetic tendons as interchangeable connectors between muscle actuators and robotic skeletons,” says lead writer Ritu Raman, an assistant professor of mechanical engineering (MechE) at MIT. “Such modularity might make it simpler to design a variety of robotic purposes, from microscale surgical instruments to adaptive, autonomous exploratory machines.”

The examine’s MIT co-authors embrace graduate college students Nicolas Castro, Maheera Bawa, Bastien Aymon, Sonika Kohli, and Angel Bu; undergraduate Annika Marschner; postdoc Ronald Heisser; alumni Sarah J. Wu and Laura Rosado; and MechE professors Martin Culpepper and Xuanhe Zhao.

Muscle’s good points

Raman and her colleagues at MIT are on the forefront of biohybrid robotics, a comparatively new area that has emerged within the final decade. They give attention to combining artificial, structural robotic components with dwelling muscle tissue as pure actuators.

“Most actuators that engineers usually work with are actually onerous to make small,” Raman says. “Previous a sure dimension, the fundamental physics doesn’t work. The great factor about muscle is, every cell is an impartial actuator that generates pressure and produces movement. So you may, in precept, make robots which might be actually small.”

Muscle actuators additionally include different benefits, which Raman’s group has already demonstrated: The tissue can develop stronger as it really works out, and may naturally heal when injured. For these causes, Raman and others envision that muscly droids might at some point be despatched out to discover environments which might be too distant or harmful for people. Such muscle-bound bots might construct up their power for unexpected traverses or heal themselves when assistance is unavailable. Biohybrid bots might additionally function small, surgical assistants that carry out delicate, microscale procedures contained in the physique.

All these future situations are motivating Raman and others to search out methods to pair dwelling muscle tissue with artificial skeletons. Designs up to now have concerned rising a band of muscle and attaching both finish to an artificial skeleton, much like looping a rubber band round two posts. When the muscle is stimulated to contract, it may pull the components of a skeleton collectively to generate a desired movement.

However Raman says this technique produces plenty of wasted muscle that’s used to connect the tissue to the skeleton quite than to make it transfer. And that connection isn’t all the time safe. Muscle is kind of mushy in contrast with skeletal buildings, and the distinction may cause muscle to tear or detach. What’s extra, it’s usually solely the contractions within the central a part of the muscle that find yourself doing any work — an quantity that’s comparatively small and generates little pressure.

“We thought, how can we cease losing muscle materials, make it extra modular so it may connect to something, and make it work extra effectively?” Raman says. “The answer the physique has give you is to have tendons which might be midway in stiffness between muscle and bone, that will let you bridge this mechanical mismatch between mushy muscle and inflexible skeleton. They’re like skinny cables that wrap round joints effectively.”

“Well related”

Of their new work, Raman and her colleagues designed synthetic tendons to attach pure muscle tissue with an artificial gripper skeleton. Their materials of alternative was hydrogel — a squishy but sturdy polymer-based gel. Raman obtained hydrogel samples from her colleague and co-author Xuanhe Zhao, who has pioneered the event of hydrogels at MIT. Zhao’s group has derived recipes for hydrogels of various toughness and stretch that may keep on with many surfaces, together with artificial and organic supplies.

To determine how robust and stretchy synthetic tendons needs to be to be able to work of their gripper design, Raman’s group first modeled the design as a easy system of three varieties of springs, every representing the central muscle, the 2 connecting tendons, and the gripper skeleton. They assigned a sure stiffness to the muscle and skeleton, which had been beforehand recognized, and used this to calculate the stiffness of the connecting tendons that might be required to be able to transfer the gripper by a desired quantity.

From this modeling, the group derived a recipe for hydrogel of a sure stiffness. As soon as the gel was made, the researchers rigorously etched the gel into skinny cables to kind synthetic tendons. They hooked up two tendons to both finish of a small pattern of muscle tissue, which they grew utilizing lab-standard strategies. They then wrapped every tendon round a small publish on the finish of every finger of the robotic gripper — a skeleton design that was developed by MechE professor Martin Culpepper, an knowledgeable in designing and constructing precision machines.

When the group stimulated the muscle to contract, the tendons in flip pulled on the gripper to pinch its fingers collectively. Over a number of experiments, the researchers discovered that the muscle-tendon gripper labored thrice quicker and produced 30 instances extra pressure in comparison with when the gripper is actuated simply with a band of muscle tissue (and with none synthetic tendons). The brand new tendon-based design additionally was capable of sustain this efficiency over 7,000 cycles, or muscle contractions.

General, Raman noticed that the addition of synthetic tendons elevated the robotic’s power-to-weight ratio by 11 instances, that means that the system required far much less muscle to just do as a lot work.

“You simply want a small piece of actuator that’s well related to the skeleton,” Raman says. “Usually, if a muscle is absolutely mushy and hooked up to one thing with excessive resistance, it’ll simply tear itself earlier than transferring something. However should you connect it to one thing like a tendon that may resist tearing, it may actually transmit its pressure via the tendon, and it may transfer a skeleton that it wouldn’t have been capable of transfer in any other case.”

The group’s new muscle-tendon design efficiently merges biology with robotics, says biomedical engineer Simone Schürle-Finke, affiliate professor of well being sciences and expertise at ETH Zürich.

“The tough-hydrogel tendons create a extra physiological muscle–tendon–bone structure, which drastically improves pressure transmission, sturdiness, and modularity,” says Schürle-Finke, who was not concerned with the examine. “This strikes the sphere towards biohybrid techniques that may function repeatably and finally perform outdoors the lab.”

With the brand new synthetic tendons in place, Raman’s group is transferring ahead to develop different components, comparable to skin-like protecting casings, to allow muscle-powered robots in sensible, real-world settings.

This analysis was supported, partially, by the U.S. Division of Protection Military Analysis Workplace, the MIT Analysis Help Committee, and the Nationwide Science Basis.

MIT Information