Rensselaer Polytechnic Institute (RPI) is working with Titomic to advance its Titomic Kinetic Fusion know-how for lithium-ion battery (LIB) electrode manufacturing.

With assist from the Nationwide Science Basis (NSF) Power Storage Engine in Upstate New York Program, the 2 organisations are creating chilly spray–based mostly dry-coating applied sciences.

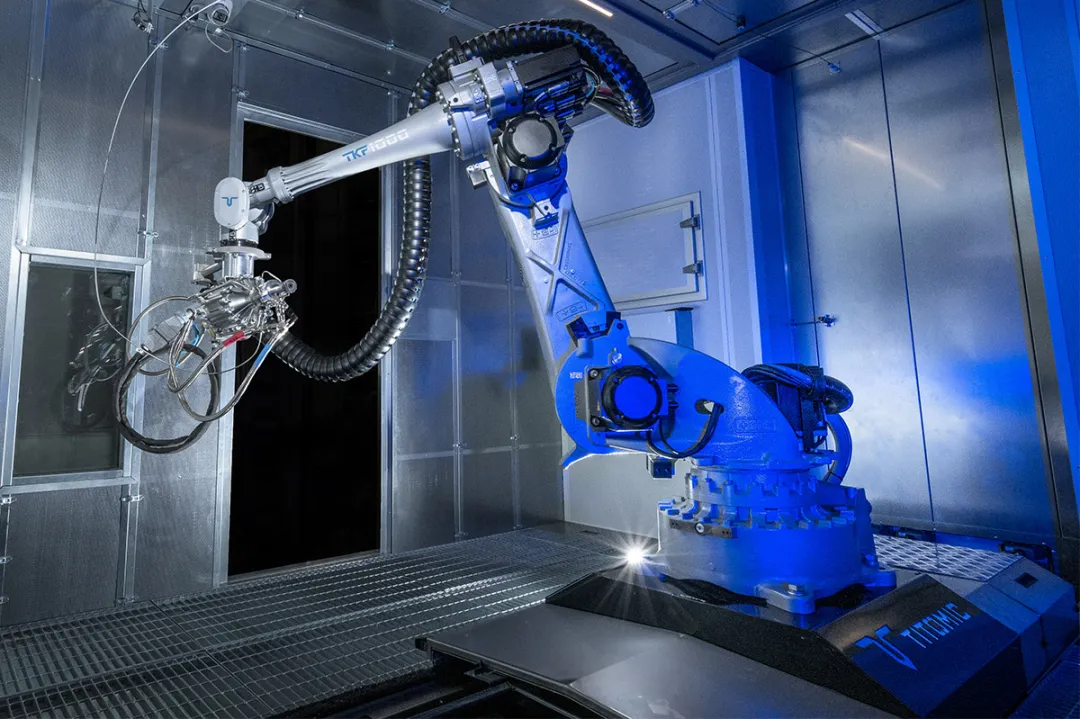

Titomic’s TKF cold-spray strategy is claimed to get rid of the power and time-intensive levels by instantly depositing electrode powders onto aluminium or copper foils. This, the companions say, could be seamlessly built-in into current roll-to-roll manufacturing strains or tailored for 3D printed electrodes with customised geometries and compositions.

A technical programme structured in 4 phases will search to develop the answer within the lab and chart a pathway into business. First, a cloth feasibility effort will conduct trials of candidate anode and cathode powders (similar to silicon, LTO, LMO, and LFP) deposited onto foil substrates, with detailed micro- and macro-level characterisation to find out spray parameters. The down-selection & demonstrator part will then develop electrode demonstrators that may meet business necessities earlier than a pilot-scale system is deployed with a buyer’s LIB roll-to-roll manufacturing line. Lastly, an in depth scalability and value evaluation will likely be carried out to judge the transition from laboratory demonstrations to large-scale business functions.

By this programme, the companions hope to deal with crucial business wants for extra sustainable, environment friendly, and scalable electrode manufacturing.

“This deposition breakthrough represents a pivotal second in our growth into the clear power sector,” stated Jim Simpson, Titomic CEO and Managing Director. “By making use of our confirmed TKF chilly spray know-how to battery electrode manufacturing, Titomic helps to beat long-standing effectivity and sustainability challenges in lithium-ion manufacturing. This improvement not solely advantages our clients but additionally helps the worldwide transition to renewable power and electrification.”

“By instantly depositing practical electrode supplies through chilly spray know-how—with out the necessity for binders, solvents, or drying steps—we’re addressing crucial inefficiencies in conventional slurry-based LIB manufacturing,” added Prof. Semih Akin and Prof. Nikhil Koratkar, NSF venture PIs from Rensselaer Polytechnic Institute. “Titomic’s devoted chilly spray programs allow direct and high-throughput deposition of LIB electrodes, serving to to speed up the transition towards renewable power adoption and widespread electrification.”