February 2019 Hacker of the Month, Michael Graham, makes use of 3D printing as his mainstay instrument in testing and prototyping instruments and supplies for his engineering builds.

Posted on January 28, 2019

by

Chris Morgan

As a analysis and improvement mechanical engineer, Michael Graham has seen a couple of totally different sorts of expertise come and go. However as soon as a school good friend talked about 3D printing to him, he was hooked.

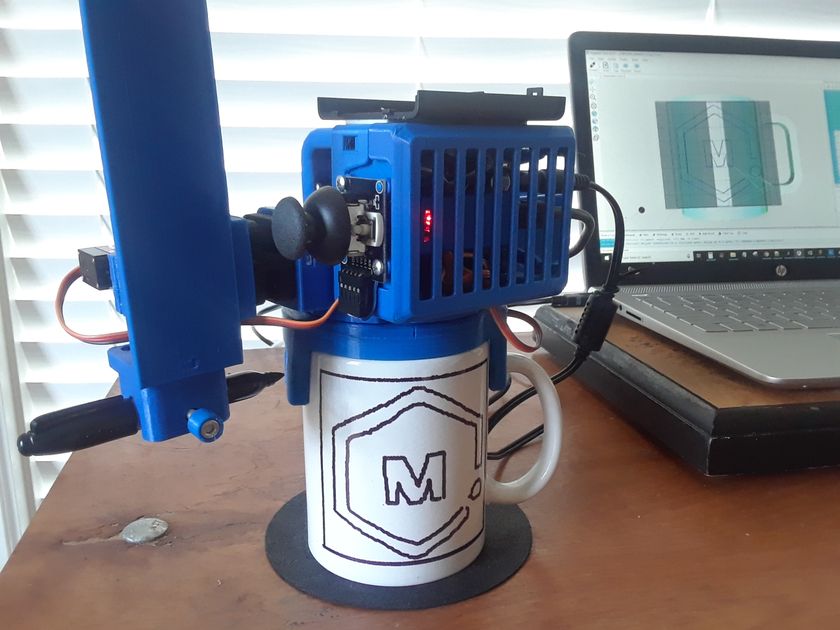

A busy day for the Mug-O-Matic

Since 2011 Michael has labored as a contractor and engineer designing and constructing specialty machines and industrial gear. He has additionally dabbled in 3D printing via his profession, most notably with HP’s multi-jet Fusion 3D printer, and infrequently elsewhere. However in 2012 he picked up an unique Printrbot with the 3D printed and laser lower {hardware} to construct it for the educational expertise.

“I noticed individuals making trinkets on Thingiverse however truthfully I had no concept what I’d use the machine for. It simply appeared like a doubtlessly useful gizmo and a profession ability to choose up.”

The Superb Mug-O-Matic!

As soon as he moved from the Midwest to Portland, Oregon and found the PDX 3D Printing Lab meetup and the thriving maker neighborhood, he had discovered his tribe of fellow ‘layer geeks’. They meet month-to-month to share tales and nerd out. In addition they contribute a heavy presence to the annual Portland MakerFaire.

As an engineer, Michael has created checks, jigs and fixtures, and lots of different designs. One among his main engineering experiments got here after he grew to become curious concerning the energy of the totally different infill patterns utilized by most 3D printers. So, he constructed a check machine and decided that the rectilinear infill sample was not solely the quickest to 3D print, nevertheless it additionally resulted in a better last half energy/weight ratio in comparison with a honeycomb fill. He additionally decided that perimeters have a far better impact on half energy than infill does by way of energy gained/plastic used. These outcomes helped Michael mannequin the present strategies he makes use of to design his 3D prints. An engineer all the best way!

Michael’s Common Take a look at Machine

Whereas he has a store with a lathe, a mill, and different bigger manufacturing machines, he makes use of his 3D printer probably the most. He enjoys seeing the fruits of his labor extra simply repeated and shared. He primarily makes use of a Prusa Mk3 to manufacture his designs.

Michael’s principal challenge for the time being is the Mug-O-Matic TinyCNC drawing robotic. The Mug-O-Matic is an open-source, extremely modifiable mug printing robotic that makes use of markers, and the path of the creator who makes it, to brighten favourite espresso receptacles with enjoyable designs.

Michael’s Gear Gentle Swap Cowl

“I’ve experimented with constructing a machine to routinely acetone vapor polish abs plastic utilizing an ultrasonic mister. It labored fairly effectively nevertheless it was undoubtedly a hack. These days I’ve my thoughts set on producing novelty robotic kits and my designs particularly DO NOT require any post-processing since that drastically will increase the man-hours wanted to supply them. The imaginative and prescient is to actually scrape elements off the print bend and drop them right into a delivery field, with none useful compromises being made.”

Michael is continually pushed by curiosity and a need to develop and apply new expertise. This lead him to the creation of the Mug-O-Matic, “This explicit work was impressed by a wide range of initiatives found on-line via my curiosity in making toys and constructing automated gear. I actually just like the ‘Eggbot’ egg plotter specifically and the way significantly it takes its foolish job. I needed to create my very own little job particular robotic too, besides with an output that has extra on a regular basis enchantment than eggs. I believed hmm…I drink espresso on daily basis & I’ve by no means seen a espresso mug plotter earlier than. Sounds enjoyable! Finally, my toy has totally different priorities than the eggbot, so I take advantage of totally different expertise and commerce off a lowered drawing decision to realize a cheaper price level.”

Michael’s Selfmade Vapor Polisher for ABS

However as a realist, Michael is aware of that supplies for initiatives must be attainable by everybody, so he makes use of off-the-shelf supplies, as a rule, so everybody can reap the benefits of his creations. Solely when he can’t buy a ready-made resolution does he begin designing new elements. At that time, he makes use of no matter materials it takes to get the job achieved proper.

Michael has put his abilities to good use, successful a number of design contests sponsored by Instructables.com, Thingiverse, Pinshape, and others. He attributes his success to placing in a critical effort to make a inventive, unique, and reproducible challenge with wonderful documentation. His hottest initiatives have a number of hundred thousand views on his engineerdog.com web site (hyperlinks under).

For the longer term, Michael has many initiatives to work on, however he has a weak point that many people share, “ I attempt to not neglect that the most harmful factor affecting my capability to finish a given challenge is…my subsequent challenge! So I attempt to not do two initiatives without delay. That stated, down the highway, I’d have an interest to construct an expert (open-source) model of my TesterBot machine and supply a mechanical testing service. The one limitation is discovering paying shoppers first!”

A 3-wheeled design challenge Michael labored on in school.

We look ahead to seeing extra of Michael’s designs come to life sooner or later! To see extra of what Michael is as much as, go to his web site right here:

You may as well see Michaels’ designs on Thingiverse right here:

Do you assume you’ve gotten what it takes to be our subsequent Hacker of the Month? Merely comply with us on Fb/Twitter or electronic mail chris.morgan@matterhackers.com. Inform us about your challenge or 3D printed creation, and you possibly can be featured in our subsequent e-newsletter. The Hacker of the Month can even obtain a free spool of PRO Sequence or MH Construct filament to additional their pursuit of 3D printing greatness.