Researchers from McGill College’s Division of Mechanical Engineering and at Drexel College have developed a brand new methodology for high-resolution 3D printing utilizing the proboscis of a feminine mosquito as a organic nozzle.

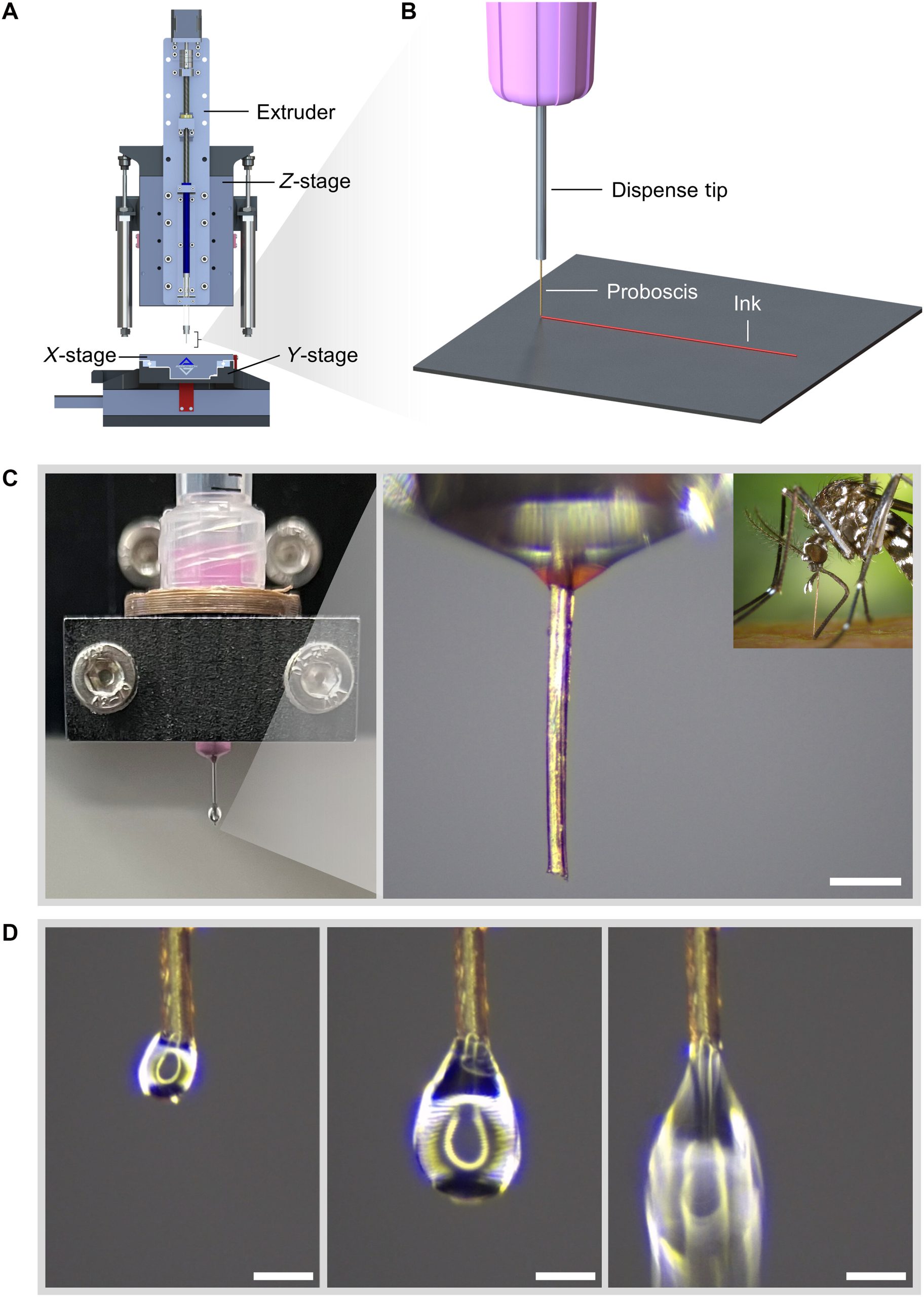

As per the analysis, the examine describes what the authors name “3D necroprinting,” wherein proboscides taken from laboratory-reared, uninfected and deceased mosquitoes are mounted onto a {custom} printer and used to extrude viscous inks and bioinks by a channel usually about 20 to 25 µm extensive. As a result of that is smaller than frequent business micro-dispense suggestions, the system can produce printed strains on the order of 18 to twenty-eight µm, with demonstrations round 20 to 22 µm.

“Excessive-resolution 3D printing and microdispensing depend on ultrafine nozzles, usually created from specialised metallic or glass,” stated examine co-author Jianyu Li, Affiliate Professor and Canada Analysis Chair in Tissue Restore and Regeneration at McGill. “These nozzles are costly, tough to fabricate and generate environmental waste and well being considerations.”

Evaluating the mosquito proboscis nozzle

The researchers started by surveying many organic buildings that naturally transport fluids, together with stingers, fangs, harpoons, claws, plant xylem vessels, and bug proboscides. They chose the feminine mosquito proboscis as a result of it’s comparatively straight, stiff for a organic materials, straightforward to deal with, and already types a sealed hole tube for feeding. Its interior diameter is round 20 to 25 µm and its size is about 2 mm, which is brief sufficient to restrict backpressure whereas remaining sensible to mount.

Mechanical testing confirmed that the proboscis can tolerate inside pressures of about 60 kPa earlier than rupturing. Burst checks mixed with a thin-walled stress vessel mannequin indicated that failure is ruled by circumferential stress within the wall, with an estimated essential hoop stress at failure of roughly 708 kPa. When failure happens, it takes the type of an axial crack alongside the size of the proboscis.

To make use of it as a nozzle, the crew bonded the proboscis to the outlet of an ordinary syringe tip utilizing a small adapter and UV-curable resin, making a steady movement path. The printer is a custom-built direct ink writing system with a piston-driven extruder and a high-resolution movement stage. The crew demonstrated extrusion of generally used bioinks, together with Cellink Begin bioink gel and Pluronic F-127 bioink gel.

Two predominant failure modes had been noticed. In a single, shear-thinning ink accrued close to the outlet and partially solidified when shear stress was eliminated, making a blockage and a neighborhood stress buildup that triggered rupture close to the tip. Within the different, inks with very excessive obvious viscosity required a lot backpressure that the proboscis ruptured close to its inlet. Utilizing rheological measurements and the Herschel-Bulkley movement mannequin, the authors outlined working limits that keep away from each varieties of failure.

Additionally they recognized a course of window that balances ink extrusion pace and nozzle motion. Inside this window, the system printed buildings together with a honeycomb about 600 µm throughout, a maple leaf about 900 µm throughout, and grid scaffolds. Some printed strains reached widths of about 18 µm.

The group additionally printed cell-laden inks containing B16 melanoma cells and purple blood cells. Printed scaffolds confirmed a post-printing cell viability of about 86%, indicating that shear stresses within the organic nozzle didn’t trigger widespread cell injury. A proof-of-concept check additionally confirmed uptake and redeposition of small volumes of hydrogel right into a tissue analogue.

In contrast with glass-pulled pipettes, which might attain diameters beneath 1 µm however are brittle, variable, nonbiodegradable, and costly, mosquito proboscides are biodegradable, constant in measurement, and low value. The examine additionally discovered that proboscides stay usable for a number of days at room circumstances and for much longer when frozen, and that inside floor roughness has a negligible impact on movement.

The work doesn’t suggest common alternative of typical nozzles, however reveals its potential as a low-cost, environmentally sustainable different to metallic and plastic nozzles.

Pushing 3D printing to microscales

Past McGill, researchers at College of Illinois Urbana-Champaign reported a direct ink writing methodology known as 3D printing by speedy solvent trade (3DPX) that enabled fabrication of ultra-fine polymer fibers all the way down to 1.5 µm in diameter utilizing a 5 µm nozzle, with facet ratios exceeding 3,400.

Utilizing speedy solvent trade, filaments solidified virtually immediately at speeds as much as 5 mm/s, stopping capillary breakup and sustaining stability. The crew demonstrated centimeter-scale fibers, hair-like arrays, and curved buildings, confirmed compatibility with a number of polymers and nanocomposites, and used multi-nozzle printing for parallel fabrication, establishing a brand new decision benchmark for embedded direct ink writing.

Moreover, Stanford College researchers developed a roll-to-roll model of steady liquid interface manufacturing (r2rCLIP) that used a shifting PET movie to switch a stationary construct plate. This enabled a completely automated line for printing, washing, curing, and eradicating microscale elements at charges approaching a million particles per day.

Led by Joseph DeSimone’s group, the system demonstrated high-resolution, high-throughput micro-3D printing for scalable manufacturing in areas similar to drug supply, microrobotics, and superior supplies.

The researchers’ findings are detailed of their paper titled “3D Necroprinting: Leveraging biotic materials because the nozzle for 3D printing,” by Justin Puma, Megan Creighton, Ali Afify, Jianyu Li, Changhong Cao, Evan Johnston, Hongyu Hou, Lingzhi Zhang, Zixin He, Zixin Zhang, Xiaoyi Lan, Zhen Yang et al, was revealed in Science Advances.

The 3D Printing Trade Awards are again. Make your nominations now.

Do you use a 3D printing start-up? Attain readers, potential traders, and clients with the 3D Printing Trade Begin-up of 12 months competitors.

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or observe us on LinkedIn.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals the idea and configuration of 3D necroprinting. Picture through McGill College.