The current introduction of person outlined directions in AutomationDirect PLCs gives one other software for accelerating PLC and HMI growth.

By Tim Ensminger, AutomationDirect

Many industrial automation merchandise and practices have been developed as extra strong variations of commercial-grade applied sciences. As microprocessors, reminiscence, and communications {hardware} and software program have advanced all through the knowledge know-how (IT) world, they have been generally tailored to fulfill the calls for of always-on functions in harsh operational know-how (OT) environments, delivering economical but high-performing options.

This strategy is just not solely about making more durable {hardware}. It’s equally vital to think about the software program programming and knowledge dealing with capabilities of a platform. Each programmable logic controllers (PLCs) and human-machine interfaces (HMIs) employed for OT industrial automation functions have benefited from adopting IT-based object-oriented programming (OOP) ideas to hurry growth and enhance consistency and efficiency. The most recent instance is the introduction of person outlined directions (UDIs) into the AutomationDirect Productiveness PLC built-in growth atmosphere (IDE).

Object-Oriented Necessities

By encapsulating performance and knowledge, OOP empowers builders to create a typical software program construction after which replicate or instantiate it as wanted. A developer can defend info and logic inside an occasion of the construction, and move essential info into and out of the construction as wanted. OOP allows builders to prepare their programming and configuration work in helpful methods when deploying it, utilizing it, and updating it.

A typical PLC comes with a number of primary knowledge sorts, reminiscent of bits, integers, floating level numbers, and extra. A sophisticated PLC platform empowers builders to create a user-defined construction (UDS) of information, which mixes a number of knowledge sorts in a helpful manner. For instance, a temperature scaling knowledge construction may embrace the uncooked enter sign, the engineering minimal/most, the scaled output, and excessive/low alarm thresholds and bits. If it turns into essential to revise the UDS—maybe so as to add a scaled output common—this may be accomplished as soon as and robotically propagated all through the cases.

So as to present this knowledge construction to an operator in a concise method, an HMI just like the AutomationDirect C-more CM5 sequence has provisions for builders to create graphical objects from primary static and dynamic components, and hyperlink them to a UDS within the PLC. For the temperature instance, the developer could create an information field which shows the scaled temperature, and adjustments shade upon excessive or low alarm.

Logic Directions as an Object

OT applied sciences of every kind sometimes develop later and extra slowly than their IT precursors. Essentially the most basic PLC programming language of all, ladder logic, was particularly developed to look extra like electrical wiring diagrams and fewer like programming, so it will be extra accessible for factory-floor technicians. After all, PLC languages have developed over time to incorporate superior logical, mathematical, course of management, movement management, and different performance.

Whereas some PLC platforms have had provisions for user-defined logic for a few years, this functionality is a little bit of a step change from primary ladder programming. AutomationDirect evaluated the topic extensively earlier than lastly deploying user-defined directions (UDIs) throughout their complete Productiveness PLC platform (Determine 1). One key facet included with this implementation is the power for customers to make runtime transfers after enhancing a UDI, which isn’t at all times doable with platforms from different distributors.

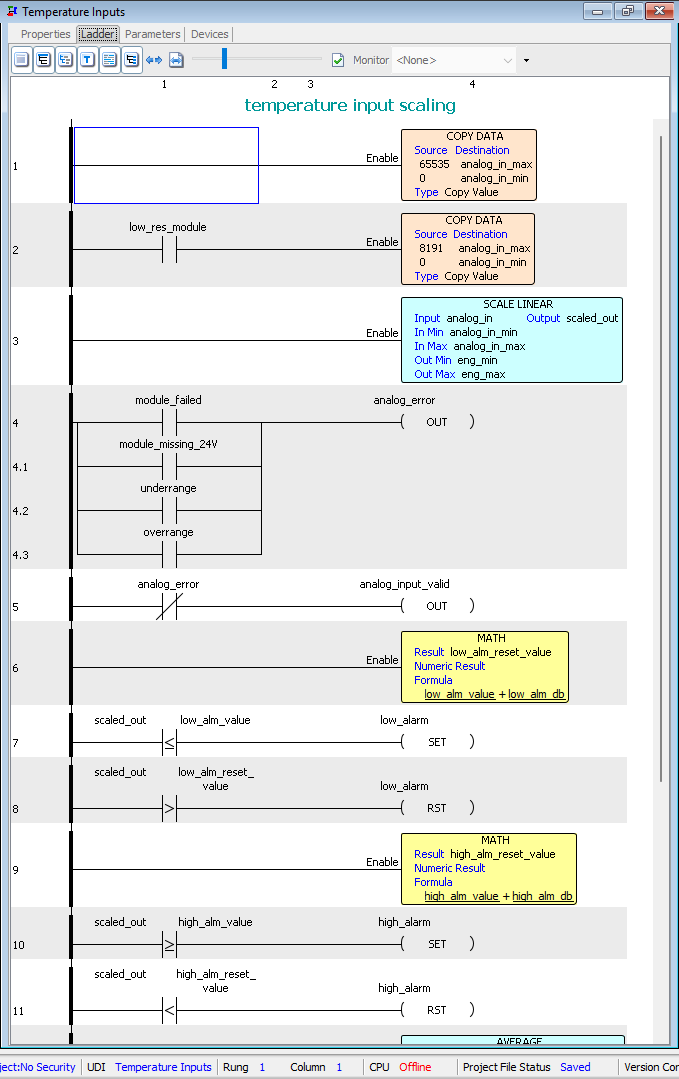

With UDI functionality, builders can encapsulate the PLC logic in an organized method. Persevering with with our temperature instance, the PLC logic may embrace provisions for mathematically scaling the worth, monitoring module errors, and evaluating the temperature with excessive/low alarm thresholds to generate alarm bits (Determine 2).

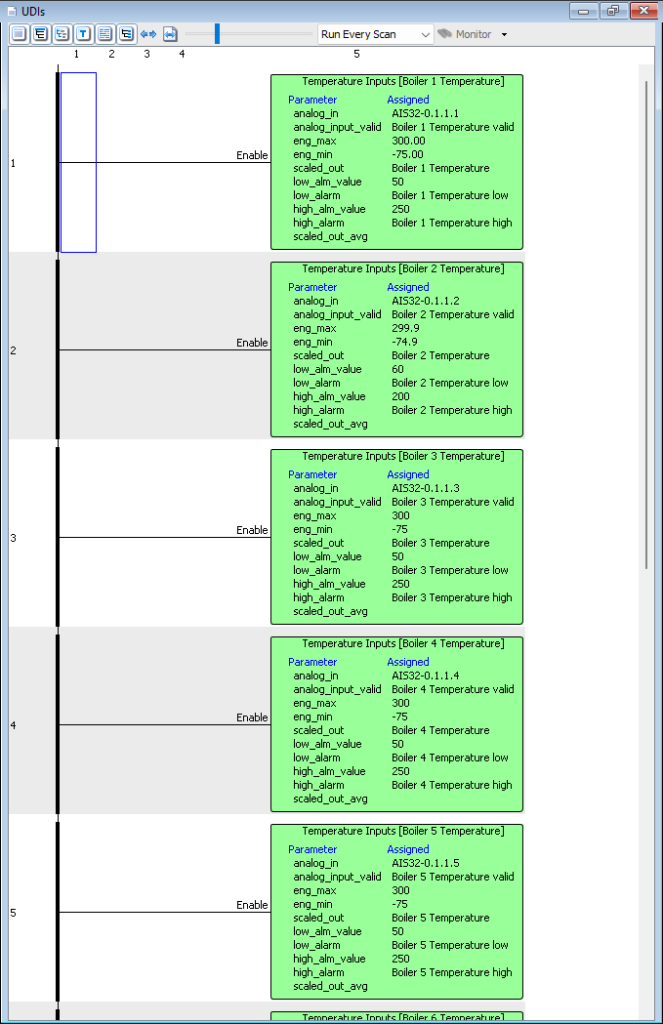

As a substitute of copying/pasting/enhancing rows of ladder directions repeatedly, the developer can instantiate the temperature scaling logic UDI as wanted and affiliate it with the correct UDS occasion and analog enter (Determine 3). If a change within the logic is important, it may be carried out as soon as and robotically propagated all through this system.

Moreover the event advantages of UDIs, this functionality allows builders, particularly authentic tools producers, to password-protect proprietary code and knowledge inside a UDI to keep away from unintended entry and operation. This UDI implementation is suitable with all Productiveness PLCs with a firmware improve, together with:

• The Productivity1000 normal stackable micro PLC

• The brand new Productivity1000 Mini PLC with on-board I/O

• The Productivity2000 micro-modular PLC

• And the top-shelf Productivity3000 modular PLC.

There are just a few caveats. Some complicated directions, reminiscent of movement management and a few communications, can’t be inside a UDI, and runtime challenge transfers could also be a bit slower. Nonetheless, the advantages actually outweigh these minor issues.

Fashionable Programming is Accessible on the Manufacturing unit Flooring

Utilizing an OOP strategy, industrial automation builders can create a library of confirmed PLC code UDIs and knowledge UDSs, together with corresponding HMI objects. This IT-originated functionality is able to use within the OT atmosphere, accelerating growth, selling reusability of confirmed code, and minimizing errors.

Creator Bio

Tim Ensminger is a product supervisor at AutomationDirect. Throughout his two decade profession, he labored primarily within the petroleum transportation business designing and commissioning management and energy methods for pipeline pump stations, tank farms, and truck loading amenities. Tim has labored at AutomationDirect since 2021 supporting the Productiveness Collection PLC merchandise. He holds a bachelor’s diploma in Electrical Engineering from Bob Jones College and a grasp’s diploma in Electrical Engineering from Clemson College.