U.S.-based metallic powder producer Continuum Powders has launched two new copper-nickel alloy powders, OptiPowder C715 and OptiPowder C964, designed to carry out reliably in difficult working situations. The powders ship sturdy corrosion resistance, constant thermal and electrical conductivity, and mechanical stability. Produced by the corporate’s proprietary Greyhound Soften-to-Powder (M2P) course of utilizing licensed reclaimed feedstock, the alloys provide excessive efficiency whereas decreasing environmental affect.

Engineered for marine, power, and industrial functions, these copper-nickel powders face up to seawater corrosion, stress-corrosion cracking, and erosion brought on by high-velocity particles. Their uniform mechanical properties throughout a large temperature vary make them appropriate for a number of additive manufacturing strategies, together with laser and electron beam powder mattress fusion, binder jetting, scorching isostatic urgent, direct power deposition, and thermal spray processes.

Precision and Sustainability in Manufacturing

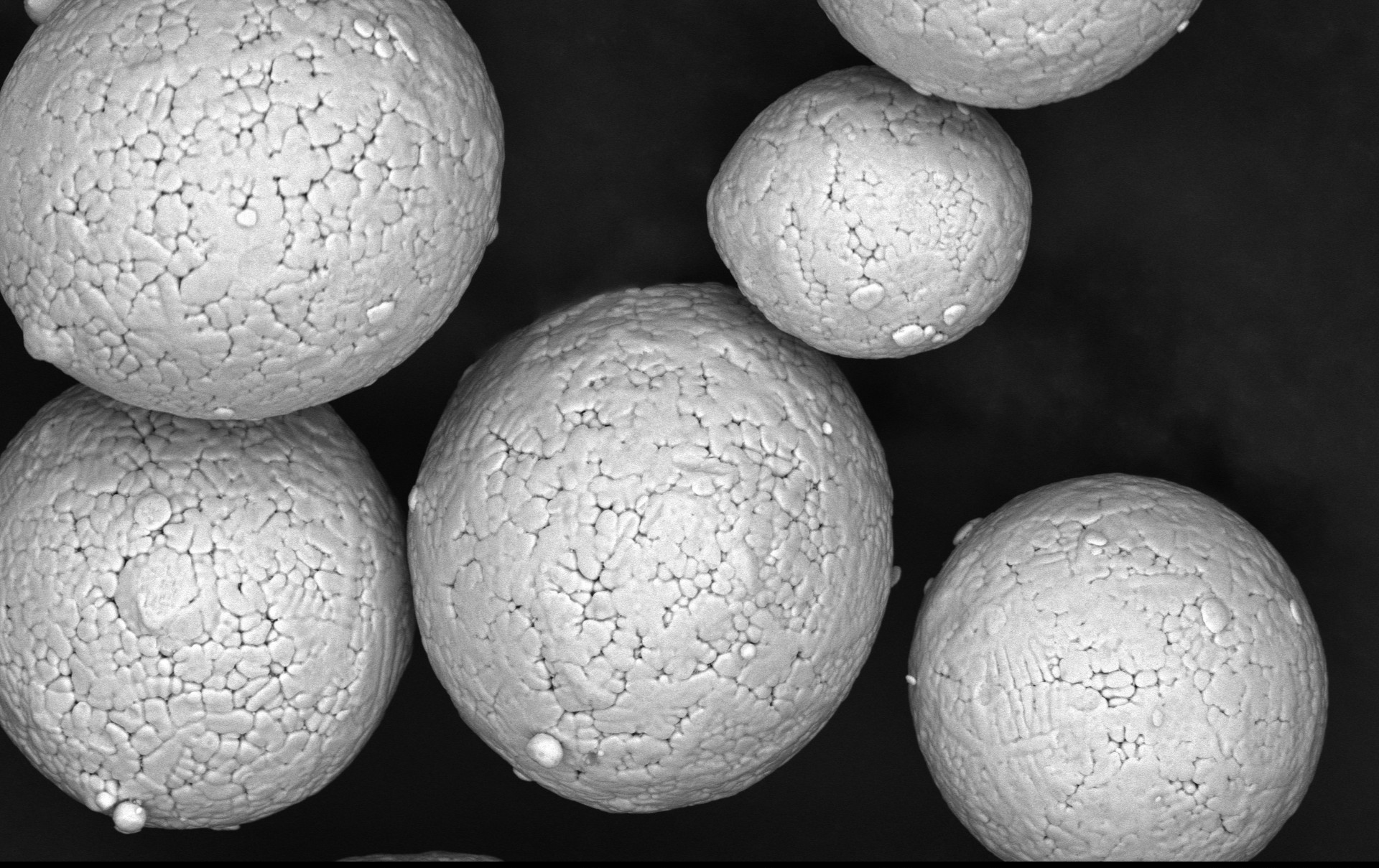

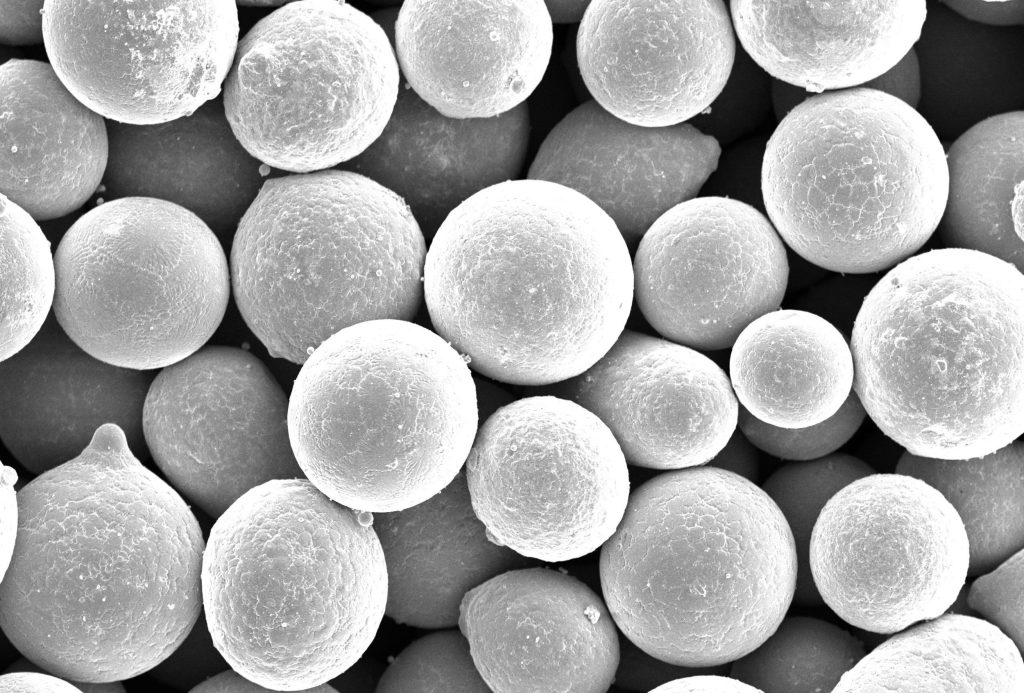

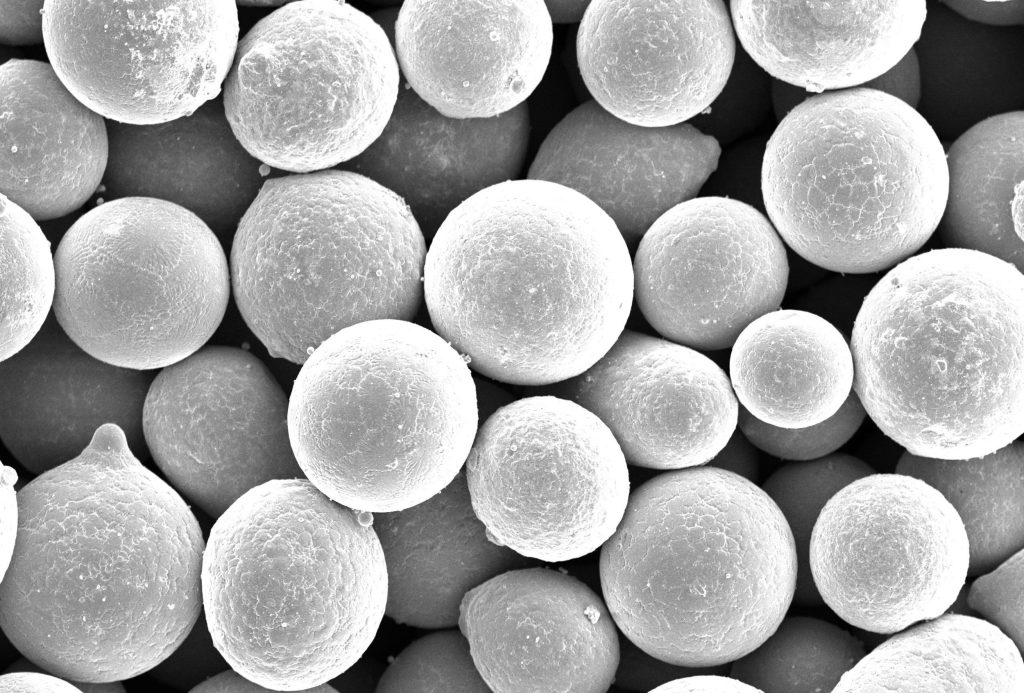

The powders are produced with M2P atomization, changing reclaimed aerospace-grade metals into high-purity, spherical particles with constant stream habits. Every batch is rigorously analyzed below Continuum’s OptiVantage framework, making certain dependable efficiency in large-scale manufacturing.

“Continuum’s major mission is to offer clients with dependable, high-performance powders,” mentioned Rob Higby, CEO Continuum Powders. “With the addition of C715 and C964, engineers working in marine, power, and industrial sectors now have entry to copper-nickel powders that mix distinctive corrosion resistance with the consistency required for production-grade additive manufacturing.”

Increasing Capabilities and Round Practices

Each powders keep steady mechanical habits at excessive temperatures whereas providing glorious thermal and electrical conductivity. They’re designed for ease of fabrication, sturdy weldability, and resistance to erosion from particles in fluid environments. A number of particle measurement choices, starting from 10–45 µm to 45–106 µm, can be found, with further customization to match particular AM platforms and processing wants.

The brand new alloys complement the corporate’s Direct Powder Feeder, which recycles unused powder again into the atomization cycle, contributing to a extra round and resilient provide chain. Wanting forward, Continuum plans to broaden its alloy portfolio, spend money on analytical and scrap-sourcing capabilities, and create co-development alternatives that enable clients to fine-tune chemistries, validate powders, and implement absolutely round feedstock methods.

Advances in 3D Printing of Metallic Alloys

Continuum’s new copper-nickel powders arrive amid a wave of improvements in metallic additive manufacturing, the place researchers are exploring new alloys and processes to reinforce efficiency and sustainability. On the Massachusetts Institute of Know-how (MIT), researchers have developed a new aluminum alloy that’s anticipated to remodel the fabrication of light-weight, high-strength components. Printed in Superior Supplies, the examine explores how fast cooling throughout laser powder mattress fusion permits aluminum to kind metastable buildings not achievable in conventional casting.

At Oak Ridge Nationwide Laboratory (ORNL), engineers are testing DuAlumin 3D, a newly developed aluminum alloy for 3D printing high-temperature automotive elements. The alloy demonstrates superior printability and mechanical efficiency in comparison with standard aluminum grades, whereas retaining glorious thermal properties.

The 3D Printing Business Awards are again. Make your nominations now.

Do you use a 3D printing start-up? Attain readers, potential buyers, and clients with the 3D Printing Business Begin-up of 12 months competitors.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business e-newsletter or observe us on Linkedin.

Featured picture reveals OptiPowder C96400. Picture through Continuum Powders.