6K Additive has been chosen because the strategic metallic powder provider for AGF Defcom, turning the U.S. producer’s metallic scrap into feedstock for additive manufacturing.

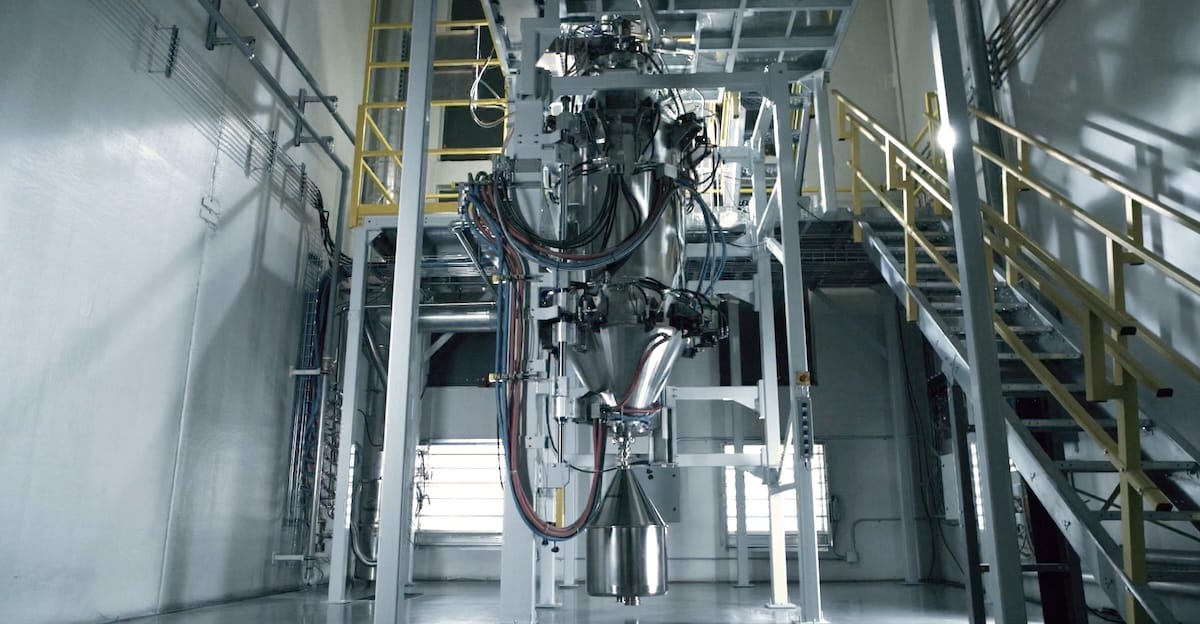

The corporate’s high-performance metallic powders might be used to 3D print suppressors and type a part of a “closed loop” upcycling program, which is able to depend on 6K Additive’s proprietary UniMelt microwave manufacturing system to fabricate premium metallic powder.

Zoltan Kovacs, proprietor and CEO of AGF Defcom mentioned, “The suppressor market is accelerating at an unprecedented tempo, and our funding in additive manufacturing is driving important curiosity. To succeed with this know-how, high-quality powder is a non-negotiable requirement. Whereas partnering with 6K Additive ensures a premium home provide, the power to upcycle our scrap is the actual recreation changer. We’ve got efficiently remodeled what was as soon as a logistical and monetary burden right into a high-value asset that instantly improves our backside line.”

In a press launch, 6K Additive famous how the elimination of the $200 federal tax stamp has resulted in pent-up demand within the suppressor market, and created an distinctive opening for superior manufacturing strategies, reminiscent of 3D printing, to fill.

“With the suppressor market rising at a staggering 265% in simply 5 years, teaming up with AGF Defcom is an ideal strategic match. They’ve a 25-year legacy of producing excellence, and we’re excited to assist their high-growth trajectory,” defined Frank Roberts, CEO of 6K Additive. “Past the enterprise growth, AGF Defcom actually understands the significance of changing scrap into high-performance powder. The truth that we’re each U.S. suppliers makes this collaboration much more important for the defence sector and home manufacturing.”