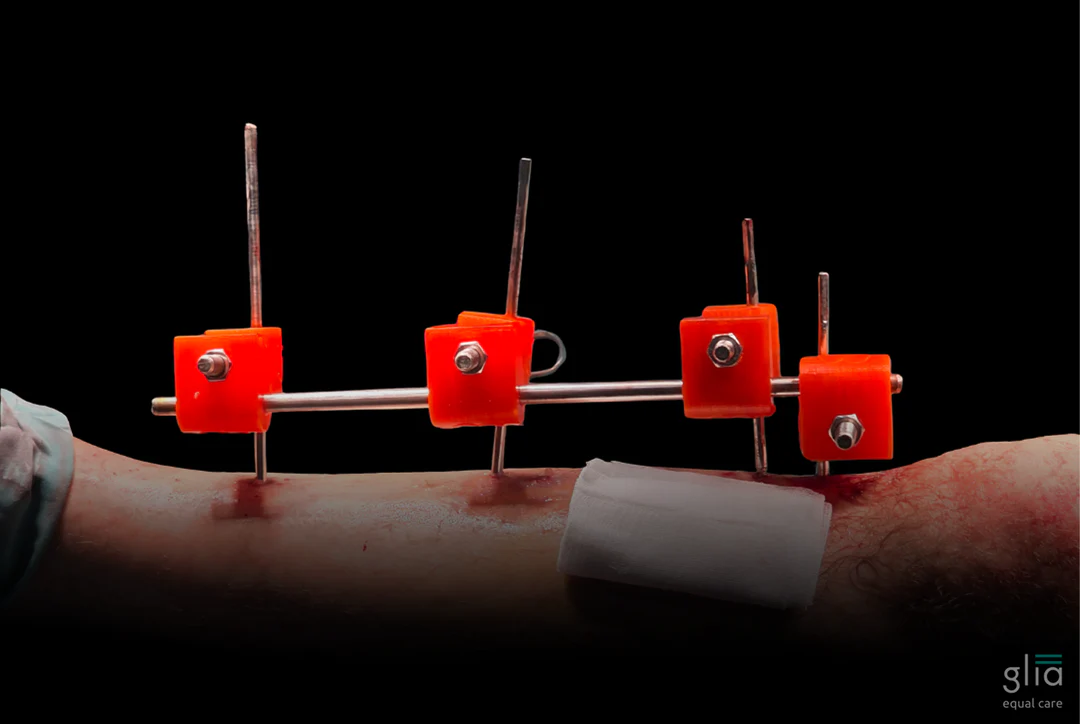

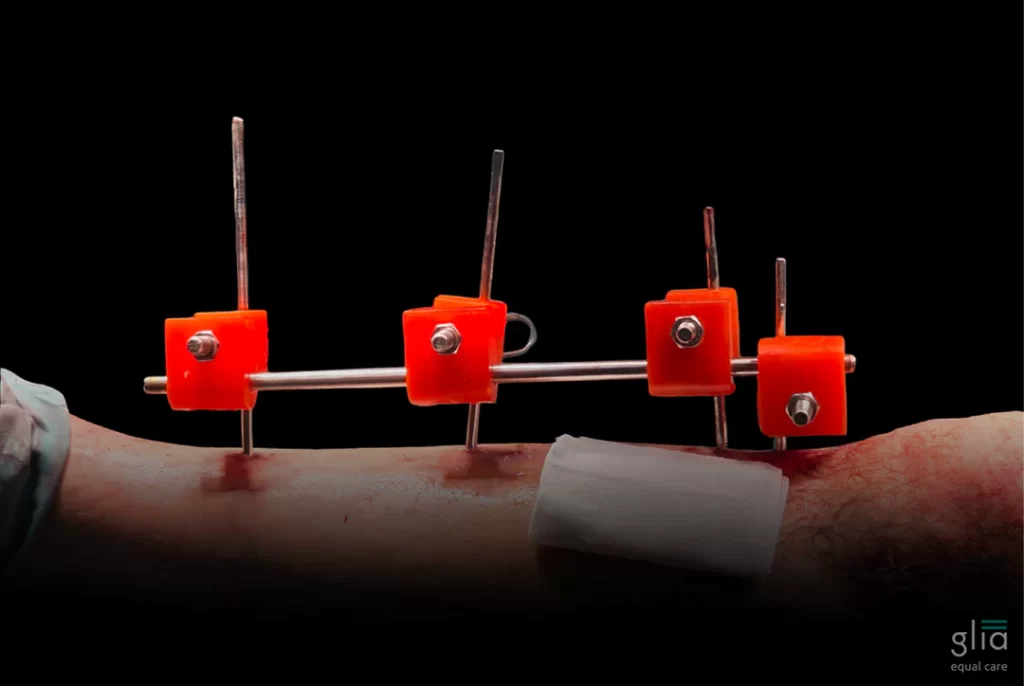

Open-source medical machine developer Glia has produced and used an exterior fixator for extreme fractures that’s designed and manufactured contained in the territory, utilizing domestically obtainable assets.

Used to stabilize complicated bone accidents, the machine is often imported, usually prices greater than $500, and depends upon established provide chains and dependable energy. In Gaza, the place greater than 90% of well being amenities have been broken or destroyed and hospitals function with severely constrained electrical energy and logistics, such tools has turn out to be troublesome or unattainable to acquire.

In opposition to that backdrop, the open-source developer says the domestically made fixator is meant to fill a spot that has turn out to be more and more onerous to bridge.

“The blockade should finish. Till then, I’m always stunned on the perseverance and steadfastness of Palestinian docs and well being care staff. They are going to do the whole lot potential to enhance care for his or her sufferers,” mentioned Dr. Ghassan Abu Sittah, Reconstructive Surgeon and Professor of Battle Medication on the American College of Beirut.

Manufacturing orthopedic units underneath siege

The fixator produced by Glia depends on a mixture of 3D printed elements, recycled plastic supplies, and tools powered by photo voltaic vitality. The group says this setup permits manufacturing to proceed even within the absence of a secure energy grid and common entry to imported provides.

Manufacturing might be completed domestically and comparatively shortly, an element that issues in treating extreme fractures the place the danger of an infection and different issues will increase with time.

The challenge didn’t start from scratch. Earlier work in collaboration with Imperial School London (ICL), centered on designing and testing preliminary variations of 3D printed elements. That analysis has since been tailored by Palestinian docs and engineers working in Gaza, lots of whom have lengthy expertise training medication and engineering in low useful resource environments.

Based on Glia, three sufferers have acquired the domestically produced fixator since August 2025. The group says these sufferers had been recovering with restored limb perform and have prevented amputation. As of November final 12 months, one other twelve sufferers had been ready to be handled utilizing the identical machine.

The design of the fixator has been launched as open supply, which means it may be reproduced or tailored elsewhere. Glia says that is meant to make the strategy usable elsewhere dealing with comparable constraints, whether or not because of battle, disasters, or weak infrastructure.

The group states that the challenge was co-designed, prototyped, and manufactured by Palestinian engineers and medical workers working throughout Gaza, Canada, and the UK, utilizing instruments and supplies thought of realistically accessible underneath present circumstances.

Fairly than presenting the work as a short lived workaround, Glia describes it as an effort to construct native technical capability to provide important medical tools when imports are unavailable.

Glia is presently looking for donations to assist the continuation and growth of the challenge by a fundraising marketing campaign hosted on Launchgood.

Additive manufacturing in humanitarian care

3D printed prosthetic and medical units have already seen use in disaster and battle zones. As an illustration, prosthetic 3D printing specialist Open Bionics delivered its 3D printed Hero Arm prostheses to a therapy facility in Germany for Ukrainian troopers injured by landmines. Manufactured within the UK, the myoelectric machine was managed by sensors within the forearm and featured a movable thumb and articulated fingers that enabled multi grip greedy.

Light-weight and customizable, the prosthesis had beforehand undergone medical analysis and was already in wider medical use. It signaled that clinically validated, 3D printed myoelectric prosthetics had been mature sufficient to be quickly deployed and fitted in frontline humanitarian and battle associated rehabilitation settings, not simply in standard healthcare methods.

Greater than a decade in the past, Not Unimaginable Labs established a 3D printing lab in a Sudanese refugee camp to provide prosthetic arms for amputees, starting with a 14 12 months previous blast sufferer. The challenge skilled native docs to make use of 3D printers and fundamental laptop instruments, enabling prosthetics to be fabricated on web site at a fee of about one arm per week.

This initiative constructed on the lab’s earlier work on the open supply, low price Eye Author machine and demonstrated a mannequin for domestically manufactured, accessible assistive applied sciences primarily based on shared designs and data.

The 3D Printing Trade Awards are again. Make your nominations now.

Do you use a 3D printing start-up? Attain readers, potential buyers, and prospects with the 3D Printing Trade Begin-up of 12 months competitors.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or observe us on LinkedIn.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits 3D printed exterior fixator. Picture by way of Glia.