Specialty tools and mechanical contractors, on this case a cryogenic programs options supplier, can prolong their challenge supply functionality by partnering with skilled automation programs integrators.

By Kyle Lamb, Quantum Automation

Excessive chilly temperature and freezing strategies are important for a lot of industries, however a few of the most demanding functions are discovered within the scientific, analysis, pharmaceutical, and medical sectors. These entities typically require using liquid nitrogen (LN2) freezers for exceptionally low-temperature and long-term storage of organic samples. All freezing applied sciences require a point of upkeep, and whereas LN2 programs usually don’t demand immense consumer interplay, their processes do require cautious storage, distribution, and replenishment of bulk liquid nitrogen.

Conventional LN2 installations are sometimes largely guide affairs or use very simplistic controls. Whereas any such fundamental performance is workable, extra superior designs present many end-user advantages. For instance, automated provide tank switching, efficient alarm supply (facilitating immediate drawback mitigation), and the flexibility to realize higher management efficiency all serve to streamline operations and supply worth.

Planning for a Cryogenic Improve

As a specialty provider of cryogenic programs options, CryoPacific is well-versed within the design, manufacturing, and set up of LN2 storage, distribution, and related tools, for utterly new tasks in addition to upgrades/updates. When a shopper requested an improve to their present LN2-based storage freezer system, it was decided that the work additionally required including extra subtle monitoring and management capabilities (Determine 1).

Determine 1: A big healthcare supplier operates quite a few LN2 tanks supplying cryogenic pattern storage tools, and required {hardware}, instrumentation, and automation upgrades to acquire higher efficiency.

The 4 present provide tanks already included fundamental instrumentation used throughout LN2 deliveries, however this shopper was due for operational visibility and automation upgrades. For example, the present system didn’t intuitively inform employees as provide tanks emptied, requiring diligent consumer consideration, and the shopper needed to enhance total efficiency by including automated tank switching. Contemplating the diploma of performance specified, CryoPacific selected to companion with an industrial automation programs integrator (SI) with full-time expertise creating management panels and making use of industrial-grade digital applied sciences.

As a result of CryoPacific was already aware of AutomationDirect merchandise and their constructive efficiency on earlier tasks, the staff used the provider’s “SIDirect” web site to analyze member SIs with demonstrated product and software experience. With a handy map interface, and filters for numerous product applied sciences and repair abilities, it was straightforward to determine well-qualified and conveniently situated SI candidates, and to pick out the most effective match for this engagement.

Quantum Automation, based mostly in Anaheim CA for over 30 years, started as an industrial product distributor and expanded through the years to supply UL508a management panel fabrication, contract manufacturing, and management programs integration companies. With expertise in renewable power, petrochemical, meals, pharmaceutical, and different associated industries, the Quantum staff had the skillset wanted to help the CryoPacific challenge.

Making a Cool Design

CryoPacific engineering started by creating a mechanical and piping design, together with circulation diagrams, to help the shopper’s wants. The work shortly transitioned into defining how one can automate the system and supply a complete consumer interface. Monitoring tank standing and ranges required specifying and putting in new strain transmitters and differential strain/stage devices, which had been specified as ProSense units sourced from AutomationDirect. As well as, new automated valves wanted to be managed by the system as nicely.

Dealing with nitrogen, particularly in comparatively enclosed areas, introduces further security issues. Nitrogen is an odorless fuel that may displace oxygen within the air, which in flip may cause unconsciousness and even demise by asphyxiation, with none prior warning indicators. Because of this, putting in and integrating oxygen monitoring and alarming programs in some of these environments are paramount for safeguarding personnel. Within the occasion {that a} low oxygen stage is detected—probably attributable to a nitrogen leak—or if any personnel provoke an emergency cease (E-stop), the LN2 management system should take motion to halt nitrogen distribution, alert operators, and maybe carry out different mitigative duties. At this web site, there was already an present constructing administration system (BMS) with oxygen detection sensors to combine with the brand new automation.

To perform this challenge, the Quantum staff specified a compact programmable logic controller (PLC) with a graphical touchscreen human-machine interface (HMI). The PLC wanted to deal with about 50 discrete enter, discrete output, and analog enter factors in whole, however the chosen controller was able to working many extra if wanted for future growth (Determine 2).

Determine 2: The AutomationDirect Productivity1000 stackable micro PLC, and a ten” C-more contact display screen HMI are compact and industrial-rated, making it straightforward to design and fabricate an operator-friendly management panel.

The implementation staff additionally wanted to contemplate that the top consumer required BACnet digital communication protocol connectivity in order that the brand new LN2 automation system might transmit alarms to the present BMS system, which would supply further visibility for customers. Subsequently, a gateway was required to transform the BACnet MS/TP (master-slave, token-passing) serial connectivity to an Ethernet Modbus TCP format appropriate for the PLC to work together with.

With these necessities established, the staff proceeded to design after which fabricate a compact management panel to accommodate the PLC, HMI, and gateway. The management panel was put in simply outdoors of the freezer space, so operators might safely work together with it even within the occasion of a nitrogen leak inside.

Improved Usability and Oversight

As soon as the automation platform was established, the staff targeted on creating PLC logic and HMI configurations. Earlier than this challenge, LN2 distribution largely relied on operators manually monitoring bodily gauges and manipulating hand-operated valves. It was important for the brand new HMI show to be simply usable by all varieties of personnel (with applicable entry credentials).

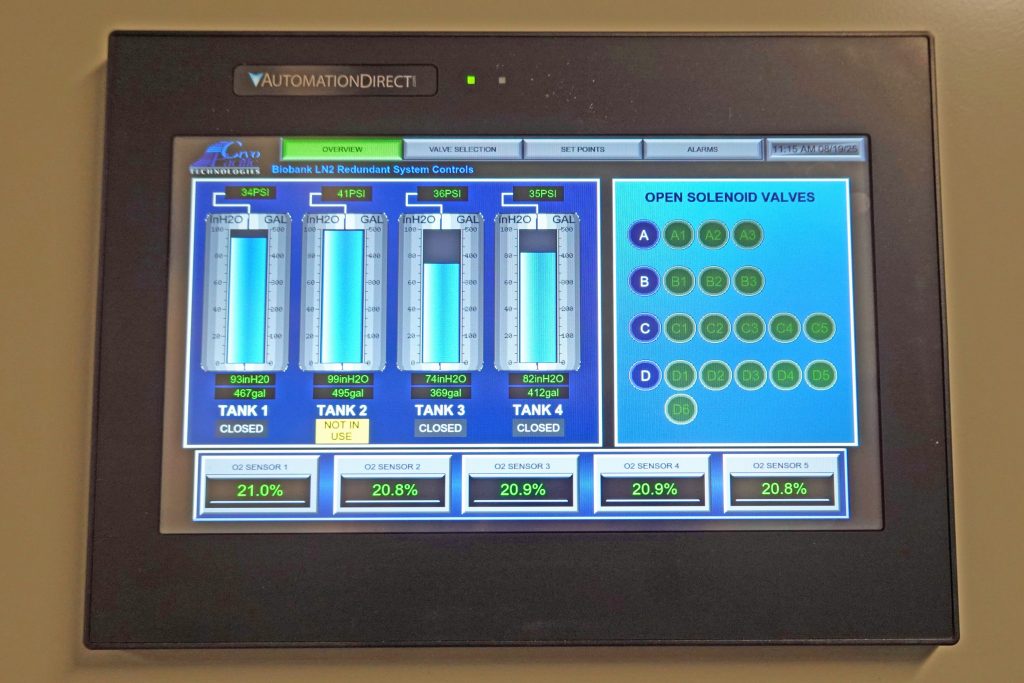

Some fundamental purposeful necessities included (Determine 3):

● Clear show of LN2 tank standing (strain, stage in inches of H2O, quantity in gallons, tank energetic or out-of-service)

● Indication of valve and refrigeration/freezing financial institution standing

● Capacity to pick out valves (which tank is major for supplying LN2, and which tank is secondary if the first goes empty)

● Configuration show for coming into setpoints

● Readouts for O2 sensors

● Show of alarms, with audible/visible indicators situated across the space

Determine 3: Though the AutomationDirect HMI monitoring and PLC management system was way more subtle and succesful than the guide strategy previously in place, the visualization and user-accessed options had been simply usable by all varieties of personnel.

Each SIs and finish customers recognize that the software program for this PLC and HMI platform is freely out there. The software program emphasizes ease-of-use along side very good performance, and the producer web site gives intensive technical supplies, coaching movies, and help choices. As well as, the PLC software program additionally has an built-in simulation mode, so the management logic and related HMI graphics might largely be pre-tested on the benchtop previous to area deployment and commissioning. The power to preview operation with the top consumer supplied a excessive stage of confidence within the configuration, together with diminished danger and area prices.

The Chilly Details of Success

This cryogenic challenge is consultant of a mess of comparable undertakings worldwide, the place designers apply incremental upgrades and new applied sciences to replace present programs and enhance efficiency. The contractors and authentic tools producers (OEMs) who carry out any such work want entry to confirmed automation merchandise, and oftentimes depend on SIs specializing within the implementation of those applied sciences. Because of this challenge’s success, CryoPacific and Quantum anticipate future work collectively.

Quantum wrapped up this challenge by producing a useful consumer guide, and performing on-site coaching for the top consumer. Despite the fact that this automated system was a step change up from the legacy LN2 administration strategy, the shopper simply adjusted to the brand new capabilities and instantly took benefit of improved alarm notifications, visibility, and automated valve management to enhance operational efficiency.

All figures courtesy of Quantum Automation

Creator Bio

Kyle Lamb is the engineering supervisor at Quantum Automation, having joined the staff over seven years prior as an intern whereas attending school. From designing management panels and schematics, to performing PLC programming, HMI configuration, and full system integrations, Kyle focuses on delivering dependable and environment friendly options for shoppers. Kyle holds a bachelor’s diploma in mechanical engineering at California State College, Fullerton.